Back to products

6K - Upper Shaft Bevel Gear

$2.00piece

50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)

$5.00piece

BZ-008-C (50WF1-043 Hook Gear/341 Pinion) and BZ-009-C (50WF1-040 Lower Shaft/341 Gear Wheel) are exclusive supporting spiral bevel gears for 341 model sewing equipment. Both are made of 20CrMo and processed through multiple precision processes. Core parameters: pressure angle 20°, module 0.7, helix angle 36.393° (right-hand/left-hand rotation respectively); BZ-008-C: 16 teeth, speed ratio 2, inner diameter 7.94mm, addendum diameter 12mm, weight 0.0617kg; BZ-009-C: 32 teeth, inner diameter 9.5mm, addendum diameter 29.421mm, weight 0.0303kg. Used in supporting pairs, they feature precise and stable transmission, suitable for the transmission needs of sewing equipment.

SKU:

BZ-008-CandBZ-009-C

分类: Spiral Bevel Gears

描述

Both BZ-008-C and BZ-009-C are spiral bevel gears specially developed and designed for sewing equipment. They are made of the same high-quality 20CrMo alloy structural steel, featuring excellent strength, toughness and wear resistance. They can accurately meet the core requirements of high-frequency transmission, low noise and high stability for sewing gears, and are key supporting components in the transmission system of 341 model sewing equipment.

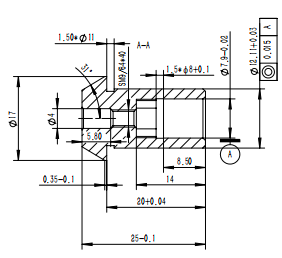

Among them, BZ-008-C corresponds to model 50WF1-043, specifically a hook gear (341 pinion). Its core technical parameters are accurately matched to the transmission requirements of the 341 model: pressure angle 20°, module 0.7, number of teeth 16, speed ratio 2, helix angle 36.393° (right-hand rotation, marked as 36.393°/R); the key dimensional parameters are as follows: inner diameter 7.94mm, tooth outer diameter 12mm, total length 25mm, and the net weight of the product is only 0.0617kg. The lightweight and compact structural design can effectively save the internal installation space of the equipment. This product adopts a refined full-process manufacturing process, sequentially going through eight core processes: normalizing, turning, gear milling, heat treatment, shot blasting, outer diameter grinding, boring and deburring. Precision is strictly controlled in each link; in particular, the outer diameter grinding and boring processes further improve dimensional accuracy, and the deburring process ensures no burrs on the surface of the component, ultimately guaranteeing smooth gear meshing and precise and efficient transmission.

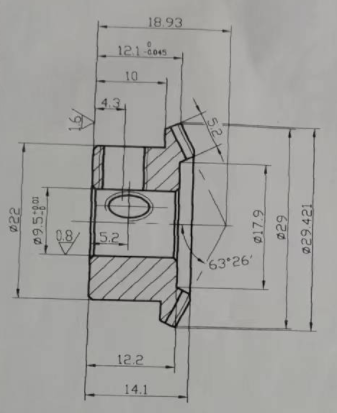

BZ-009-C corresponds to model 50WF1-040, which is a lower shaft (341 gear wheel) and forms an exclusive supporting combination with BZ-008-C. It has the same material and its core parameters achieve precise adaptation: the pressure angle is also 20°, module 0.7, number of teeth 32 (twice that of BZ-008-C), helix angle 36.393° (left-hand rotation, marked as 36.393°/L); in terms of dimensions, inner diameter 9.5mm, tooth outer diameter 29.421mm, total length 14.1mm, net weight 0.0303kg. Its manufacturing process adopts a targeted optimized design, sequentially going through six core processes: normalizing, turning, gear hobbing, heat treatment, shot blasting and reaming. Gear hobbing ensures tooth profile accuracy and transmission adaptability, and reaming guarantees the assembly accuracy of shaft components. It also undergoes strict process control and quality inspection. Together with BZ-008-C, through the structural cooperation of left-hand and right-hand rotation and the precise ratio of tooth number and speed ratio, it jointly realizes stable power transmission of the 341 model sewing equipment.

Both products focus on the exclusive application of sewing gears. Relying on the excellent mechanical properties of 20CrMo material, precise tooth profile design and mature full-process manufacturing process, they can effectively improve the transmission stability of 341 model sewing equipment, reduce operating noise, extend the service life of the equipment, and provide core transmission guarantee for the efficient and stable operation of sewing equipment.

其他信息

| BZ-008-CandBZ-009-C weight |

0.0617and0.0303 |

|---|---|

| BZ-008-CandBZ-009-C core components |

gear |

| BZ-008-CandBZ-009-C manufacturing process |

Hobbing |

用户评价 (0)

成为第一个“50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)” 的评价者 取消回复

Shipping & Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

相关产品

142525003 – Spiral Pinion and142525004 – Spiral Gear

$3.00piece

142525003 Spiral Pinion

142525003 spiral bevel pinion (exclusive for sewing machinery): 20° pressure angle, 1.2 module, 20 teeth, 35°/L spiral angle, gear ratio 2, 12mm inner diameter, 25.85mm outer tooth diameter, 19.87mm overall length, 0.037kg weight. Made of 20CrMo via multi-step precision processes, it meets the transmission needs of sewing equipment.

142525004 Spiral Gear

142525004 spiral bevel gear (exclusive for sewing machinery): 20° pressure angle, 1.2 module, 44 teeth, 35°/R spiral angle, 15mm inner diameter, 52.3mm outer tooth diameter, 18.28mm overall length, 0.1374kg weight. Made of 20CrMo with the same precision processes, it matches 142525003 pinion for stable power transmission.

718WF14-025

$4.00piece

Bevel Gear 4037014 (Large)

$4.00piece

The 4037014 Bevel Gear (Large) is made of 20CrMnTi material and manufactured through multiple precision processes including normalization, turning, gear milling and heat treatment. Its core parameters are 20° pressure angle, 2.12 module, 33 teeth and 35° left-hand rotation, with a tooth outer diameter of 70.442mm, total length of 21.91mm and weight of 0.375kg. Specially designed for reducers, this product features stable transmission, wear resistance and durability.

Bevel Gear Shaft 4037013

$3.00piece

The 4037013 Bevel Gear Shaft is a special transmission component for reducers, made of 20CrMnTi material and manufactured through multiple precision processes including normalization, turning, keyway machining, gear milling and heat treatment. Its core parameters are 20° pressure angle, 2.12 module, 8 teeth and 35° right-hand rotation, with a shaft diameter of 17mm, total length of 78.11mm and weight of 0.1295kg. It features stable transmission, wear resistance and durability.

ECD767-2 Miniature Bevel Gear

$1.00piece

HL-T19 Right-hand Gear

$6.00piece

HL-T19 right-hand spiral bevel gear (exclusive for sewing machinery): 20° pressure angle, 1.3 module, 19 teeth, 35°/R spiral angle, 10mm inner diameter, 25mm shaft diameter, 24.7mm outer tooth diameter, 49.92mm overall length, 0.3003kg weight. Made of 20CrMo via multi-step precision processes, it meets the transmission needs of sewing equipment.

KA09104 Small Steel Gear 15T

$3.10piece

KA09104 Small Steel Gear 15T is a dedicated spiral bevel gear for reducers. Made of 20CrMnTi material, it has a pressure angle of 20°, a module of 1.54, 15 teeth, and a spiral angle of 10°/R, with a shaft diameter of 10mm, a tooth outer diameter of 28mm, a total length of 59.25mm, and a single weight of 0.0541kg. Manufactured via multiple precision machining and surface treatment processes, it delivers stable transmission and high wear resistance.

Roller Sewing Machine T26 and Roller Sewing Machine T13

$2.00piece

- T20 Spiral Bevel Gear: Material 20CrMo, pressure angle 20°, module 1, number of teeth 20, spiral angle 35°/L, inner diameter 8mm, outer diameter 21.5mm, total length 14.1mm. Manufactured through multiple precision processes, it is a dedicated transmission gear for roller sewing machines.

- T24 Long Version Spiral Bevel Gear: Material 20CrMo, pressure angle 20°, module 1, number of teeth 24, spiral angle 35°/L, inner diameter 7.94mm, outer diameter 24.5mm, total length 14.35mm, single weight 0.0213kg. With precise craftsmanship, it is suitable for the transmission needs of roller sewing machines.

评价

目前还没有评价