1533-6 Tooth Gear and 1533-T36 Gear

$2.00

1533-6 Tooth Helical Gear: 20CrMo helical gear for sewing machines, module 0.8, 6 teeth, 15.12°R helix angle, precision-engineered, stable and efficient transmission

1533-T36 Helical Gear: 20CrMo helical gear for sewing equipment, module 0.8, 36 teeth, 15.12°R helix angle, high-precision, strong adaptability

SKU:

1533-001-C and 1533-004-C

分类: Helical Gears

描述

1533-6 Tooth Helical Gear

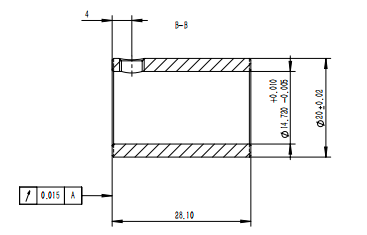

This product is a dedicated helical gear for sewing equipment, crafted from high-quality 20CrMo alloy steel, delivering excellent mechanical properties and wear resistance. Boasting precise core parameters, it features a pressure angle of 20°, module of 0.8, 6 teeth, speed ratio of 6, right-hand helix angle of 15.12°, inner diameter of 14.72mm, outer tooth diameter of 20mm, total length of 28mm, and a net weight of only 0.0235kg. Its compact and lightweight structure is perfectly suited for the lightweight installation requirements of sewing machinery.

The production process adheres to a precision workflow: normalizing – turning – screw hole machining – reaming – gear hobbing – heat treatment – shot blasting – reaming – screw assembly. Rigorous control over each process ensures the gear achieves high tooth profile accuracy and excellent meshing performance, enabling stable operation with low noise during transmission. It serves as an indispensable core transmission component that effectively guarantees the efficient and stable operation of sewing equipment.

1533-T36 Helical Gear

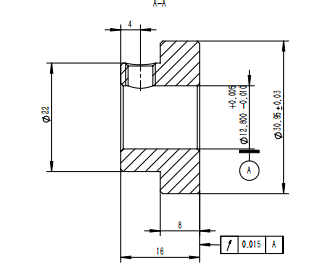

This product is a high-precision helical gear specially designed for sewing equipment, made of 20CrMo alloy steel that balances toughness and durability. It is configured with optimal key parameters: pressure angle of 20°, module of 0.8, 36 teeth, right-hand helix angle of 15.12°, inner diameter of 12.8mm, outer tooth diameter of 30.95mm, total length of 16mm, and a net weight of 0.0469kg. Its structural design matches the compact installation space constraints of sewing machinery.

The manufacturing process follows a standardized precision procedure, including normalizing – turning – screw hole machining – reaming – gear hobbing – heat treatment – shot blasting – reaming – screw assembly. The gear realizes high transmission accuracy and stable meshing, which can effectively improve the operational precision and work efficiency of sewing equipment. It is a key accessory for achieving precise power transmission in sewing machinery.

其他信息

| 1533-001-C and 1533-004-C weight |

0.0235 and 0.0469 |

|---|---|

| 1533-001-C and 1533-004-C Core Components |

gear |

| 1533-001-C and 1533-004-C |

Hobbing |

用户评价 (0)

成为第一个“1533-6 Tooth Gear and 1533-T36 Gear” 的评价者 取消回复

Shipping & Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

相关产品

1533-8 Tooth Gear and 1533-T32 Gear

$5.00piece

- 1533-8 Tooth Helical Gear: 20CrMo helical gear for sewing machines, module 0.8, 8 teeth, 20.345°R helix angle, precision-engineered for stable and efficient transmission

- 1533-T32 Helical Gear: 20CrMo helical gear for sewing equipment, module 0.8, 32 teeth, 20.345°R helix angle, high-precision with strong adaptability

2020692 Shaft

$1.00piece

2020692 gear shaft (helical gear) is made of 20CrMo, with a pressure angle of 20°, module of 0.8, 8 teeth and 15° right-hand helix angle. It has a tooth outer diameter of 10.8mm, total length of 142.3mm and weight of 0.0870kg. Produced via precision processes including hobbing, heat treatment correction and multiple grinding, it is a dedicated transmission component for power tools.

2024351 Finished Product

$2.00piece

The 2024351 finished helical gear (dedicated for power tools) has a pressure angle of 20°, module of 1.25, 41 teeth and helix angle of 5°/R. With an inner diameter of 16mm, outer diameter of 53.45mm, total length of 10mm and weight of 0.0962kg, it is made of 20CrMnTi material through precision processes including normalizing, hobbing and heat treatment, featuring stable transmission, wear resistance and impact resistance.

2024409(2024502)

$1.00piece

The 2024409 (2024502) helical gear (dedicated for power tools) has a pressure angle of 20°, module of 1.25, 19 teeth and helix angle of 20°/R. With an inner diameter of 17mm, outer diameter of 28.9mm, total length of 12mm and weight of 0.0289kg, it is made of 20CrMnTi material through precision processes including normalizing, hobbing and heat treatment, featuring stable transmission, wear resistance and impact resistance.

211WF1-014 Finished Hook Shaft Pinion and 211WF1-005 Finished Lower Shaft Main Gear

$8.50piece

211WF1-014 Finished Hook Shaft Pinion and 211WF1-005 Finished Lower Shaft Main Gear are finished helical gears made of 20Cr, with a pressure angle of 20° and a module of 1, and both have a helix angle of 45°/L. Processed via multiple precision manufacturing procedures, they are suitable for the transmission system of sewing equipment, delivering stable transmission with excellent wear resistance.

531.06-78 45° Helical Gear (Driven) and 531.06-77 45° Helical Gear (Driving)

$3.50piece

531.06-78 Driven Helical Gear and 531.06-77 Driving Helical Gear are 45° helical gears made of 20CrMo, with a pressure angle of 20°, a module of 1 and 18 teeth. Processed via multiple precision procedures, they realize precise meshing and stable transmission, and are suitable for the transmission system of sewing equipment.

855718 Finished Lower Shaft Main Gear and 855717 Hook Shaft Pinion

$8.50piece

855718 Finished Lower Shaft Main Gear and 855717 Hook Shaft Pinion are helical gears made of 20CrMo, with a pressure angle of 20° and a module of 1, and their helix angles are set as 15°/R and 15°/L respectively. Processed via multiple precision manufacturing procedures, they are suitable for the transmission system of sewing equipment, delivering stable transmission with excellent wear resistance.

D-94-172270-91 Presser Foot Lifting Gear

$4.50piece

The D-94-172270-91 Presser Foot Lifting Gear is a helical gear made of 20CrMnTi, featuring a pressure angle of 20°, a module of 1 and 72 teeth. Processed via multiple precision procedures, it offers excellent wear resistance and corrosion protection, and is ideal for the presser foot lifting mechanism of sewing equipment with accurate and stable transmission performance.

评价

目前还没有评价